AI GEEKS Introduces an Innovative Solution for Predicting Rotating Equipment Failures

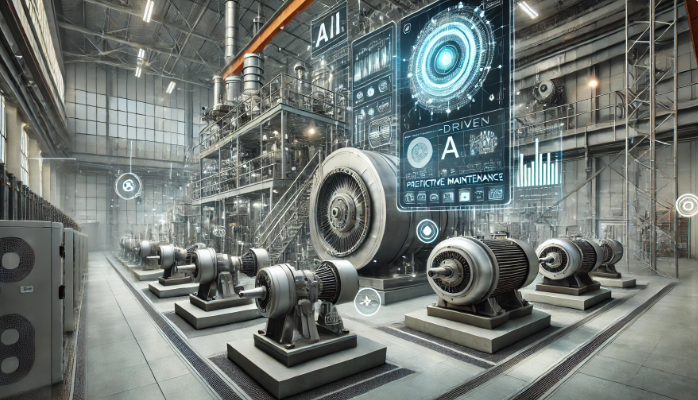

In recent years, issues with rotating equipment failures at industrial facilities, such as power plants and factories, have become increasingly critical. Rotating machines, including turbines, pumps, electric motors, compressors, and blowers, are the backbone of production, and any malfunctions can lead to significant losses, downtime, and increased maintenance costs. However, a new solution has emerged to prevent these problems, thanks to an innovative system developed by the AI GEEKS team.

AI-Powered Failure Prediction Technology

The main objective of the project was to create a predictive system based on artificial intelligence (AI) that can accurately forecast the operational condition of rotating equipment. The system operates by analyzing data collected through highly precise vibration sensors, which are widely used in industries to monitor the condition of motors and other moving parts of equipment.

Data is gathered from various vibration states, allowing even the smallest changes in equipment operation to be tracked. Specifically, the system analyzes vibrations during normal operation and detects anomalies such as vibrations caused by imbalances in the equipment or loose bolted connections.

Machine Learning Models for Accurate Predictions

To address the task, the AI GEEKS team used several machine learning approaches, including neural networks. As a result, they developed an algorithm that can predict the condition of rotating equipment with 95% accuracy based on the collected data.

The model classifies the equipment's condition and predicts whether it will operate normally or encounter anomalies. For instance, the system can identify if the equipment is vibrating due to instability in the rotating disk or loose fastenings.

Benefits for Industry

This innovative approach significantly enhances equipment maintenance efficiency. The predictive system not only reduces the number of unexpected failures but also helps optimize maintenance processes, preventing downtime and eliminating unforeseen costs. Implementing such a technology in industrial production promises to reduce downtime, speed up maintenance, and lower costs, ensuring the smooth operation of facilities.

AI GEEKS continues to develop and implement innovative solutions that are transforming approaches to equipment maintenance and operation at industrial sites, making them more efficient, safe, and cost-effective.

In recent years, issues with rotating equipment failures at industrial facilities, such as power plants and factories, have become increasingly critical. Rotating machines, including turbines, pumps, electric motors, compressors, and blowers, are the backbone of production, and any malfunctions can lead to significant losses, downtime, and increased maintenance costs. However, a new solution has emerged to prevent these problems, thanks to an innovative system developed by the AI GEEKS team.

AI-Powered Failure Prediction Technology

The main objective of the project was to create a predictive system based on artificial intelligence (AI) that can accurately forecast the operational condition of rotating equipment. The system operates by analyzing data collected through highly precise vibration sensors, which are widely used in industries to monitor the condition of motors and other moving parts of equipment.

Data is gathered from various vibration states, allowing even the smallest changes in equipment operation to be tracked. Specifically, the system analyzes vibrations during normal operation and detects anomalies such as vibrations caused by imbalances in the equipment or loose bolted connections.

Machine Learning Models for Accurate Predictions

To address the task, the AI GEEKS team used several machine learning approaches, including neural networks. As a result, they developed an algorithm that can predict the condition of rotating equipment with 95% accuracy based on the collected data.

The model classifies the equipment's condition and predicts whether it will operate normally or encounter anomalies. For instance, the system can identify if the equipment is vibrating due to instability in the rotating disk or loose fastenings.

Benefits for Industry

This innovative approach significantly enhances equipment maintenance efficiency. The predictive system not only reduces the number of unexpected failures but also helps optimize maintenance processes, preventing downtime and eliminating unforeseen costs. Implementing such a technology in industrial production promises to reduce downtime, speed up maintenance, and lower costs, ensuring the smooth operation of facilities.

AI GEEKS continues to develop and implement innovative solutions that are transforming approaches to equipment maintenance and operation at industrial sites, making them more efficient, safe, and cost-effective.