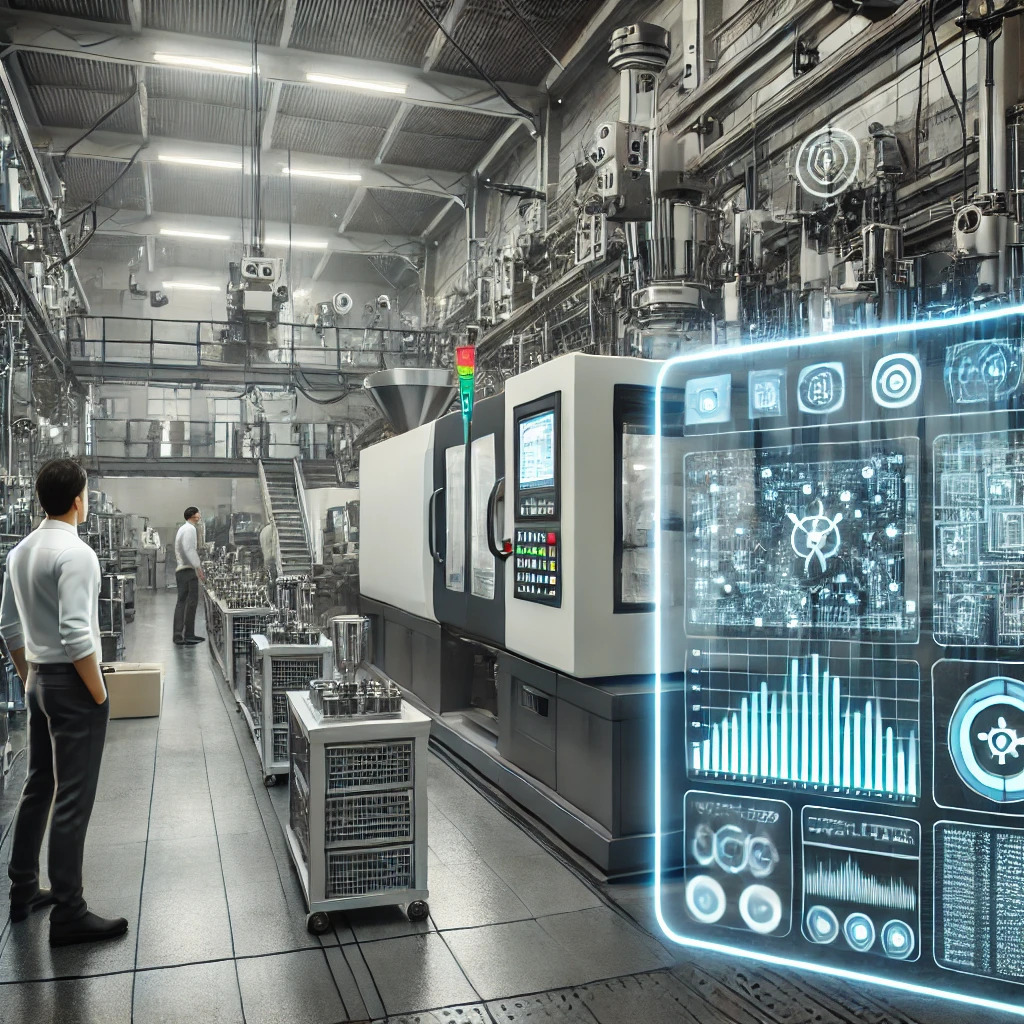

Issue: In the injection molding process, various defects frequently arise, presenting challenges for effective operational quality control. Manual inspection by operators is time-consuming and costly, with results often inconsistently recorded. Consequently, tracking and managing product quality and identifying the root causes of defects become arduous tasks.

Objective: To devise a solution for accurately assessing the quality of parts produced via injection molding machinery.

Product: Our solution entails the development of a comprehensive system to assess product quality, integrating seamlessly with foundry machine operations.

Solution: We've engineered a cutting-edge machine learning system capable of identifying diverse defect types in real-time, leveraging data collected directly from foundry machines.

Market Advantage: This innovative model facilitates substantial time savings in quality control procedures, mitigates the risk of defective products, and ultimately drives down production costs.

Objective: To devise a solution for accurately assessing the quality of parts produced via injection molding machinery.

Product: Our solution entails the development of a comprehensive system to assess product quality, integrating seamlessly with foundry machine operations.

Solution: We've engineered a cutting-edge machine learning system capable of identifying diverse defect types in real-time, leveraging data collected directly from foundry machines.

Market Advantage: This innovative model facilitates substantial time savings in quality control procedures, mitigates the risk of defective products, and ultimately drives down production costs.